From Fossil to Green Energy

With robust measurement technology from Rheonik

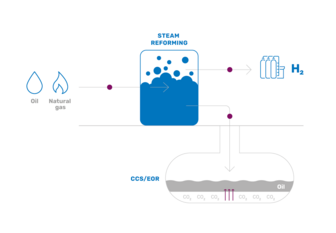

Steam reforming is currently the most widely used process for the industrial production of hydrogen. Methane, the main component of natural gas, is converted in a reactor with steam at very high temperatures using a catalyst. This process produces a hydrogen-rich gas mixture, which is purified in further process steps to almost pure hydrogen. At the same time, however, a significant amount of carbon dioxide (CO₂) is produced.

CO₂ capture and storage

A major disadvantage of steam reforming is the high level of CO₂ emissions. About ten tons of CO₂ are produced per ton of hydrogen. To minimize these emissions, the CO₂ produced can be captured and permanently stored, for example in deep geological formations. This process of CO₂ capture and storage is known as Carbon Capture and Storage (CCS).

High efficiency through robust measurement technology

Steam reforming is an established and economically efficient process for the production of hydrogen, but it is associated with high CO2 emissions. Additional measures, such as carbon capture and storage (CCS), are needed to make this process sustainable. Rheonik's Coriolis mass flowmeters make an important contribution by enabling precise monitoring and control of the relevant process flows - a crucial factor for maximum control and safety in CO₂ capture, especially under high-pressure conditions. The demanding process conditions in steam reforming - high temperatures and pressures - place high demands on measurement technology. Rheonik offers customised, heavy-duty measuring equipment that works reliably even under extreme conditions. Continuous monitoring of gas and steam flows can significantly improve efficiency, process reliability and product quality. As an experienced partner to the hydrogen economy and the oil and gas industry, Rheonik develops solutions that are precisely tailored to individual requirements - for smooth processes and maximum operational safety.

From fossil energy to a green future

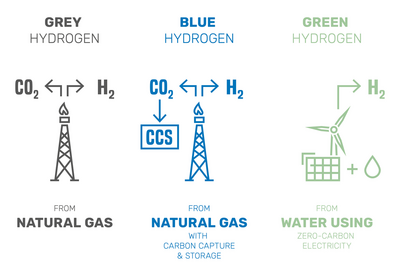

Steam reforming is an important bridging technology on the way from fossil fuels to a climate-neutral hydrogen economy. In combination with CO₂ capture, it can produce so-called "blue hydrogen" - a low-emission energy carrier that can be used immediately in existing industrial processes. In contrast, if the CO₂ produced during steam reforming is released into the atmosphere unused, it is referred to as 'gray hydrogen'. Green hydrogen, on the other hand, is produced with zero emissions, usually by electrolysis of water using renewable energy. Although this technology requires a lot of electricity, it is the most sustainable solution in the long term because it does not use fossil fuels and does not produce CO₂ emissions. The use of blue hydrogen enables a gradual transition from fossil fuels to renewable sources. In parallel with the development of green hydrogen, blue hydrogen supports the development of a scalable hydrogen infrastructure.