Consumption measurements

Shipping and Coriolis Mass flow meters

In commercial shipping, now more than ever, fuel consumption measurements are an important part of the cost-benefit analysis for making operating decisions.

Driven by emission regulations, higher-quality, low-sulphur fuels are in play and these are expensive. The MRV 757/2015 regulations require that vessels above a certain Gross tonnage (GT) need to continuously undergo verification of their CO2 footprint.

Cost-benefit data and the accurate recording of CO2 emissions have decisively changed the landscape of flow measurement technology on ships. Traditionally used volume-based measurement technology is simply no longer sufficient and the recommendation of the MRV regulations to rely on mass-based systems has driven the adoption of Coriolis mass flowmeters in their place. With the regulations in mind, it is possible to demonstrate that the higher initial cost for mass flow metering will pay off.

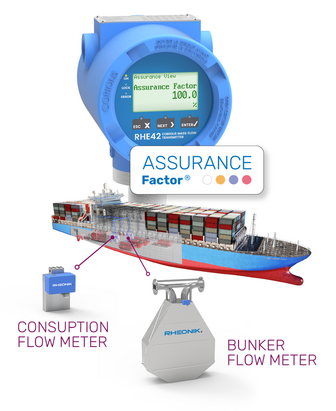

To aid acceptance of Coriolis flow meters, establishing their credibility and reliability in the challenging environment on board a ship is of crucial importance, so confirming their performance independently using standardised tests set by industry societies at accredited testing laboratories is very important. Upon satisfactory conclusion of these tests, Coriolis meters can be readily deployed for overall. Fuel consumption measurements of, amongst others, main and auxiliary engines, generators and boilers.

Marine fuels are split into two main categories: Heavy fuel oils (HFO) and distillates. HFO includes other products such as LSFO, ULSFO and HSFO. Distillates are also colloquially called marine gas oil (MGO). Mixtures of HFO and distillates frequently used in practice are described as Marine Diesel (MDO) or Intermediate Fuel Oils (IFO). The term marine diesel refers primarily to blends in which the proportion of heavy fuel oil is very small.

Challenges and solutions

- Can I believe the measurement results?

- How high are the maintenance costs each years?

- How often does a mass flow meter need to be calibrated?

- What do I have to do if updates are needed for software?

- Can I get service when I need it?

Conclusion

It's not the flow meter alone, it's the whole package that has to be right. The Rheonik team understand the very specific fuel measurement challenges in the shipping industry and this understanding helps tailor metering solutions that will provide reliable data for both controlling costs and demonstrating compliance to regulations.

Advantages of a mass flow meter

Reproducible and verifiable measurement results. Coriolis meters are able to accurately measure mass regardless of the grade/source of fuel or the fuel temperature. Unlike many volume-based technology meters, Coriolis mass flow measurements are density and viscosity independent, making reported flow rates reliable and accurate. Only with this reliable information can ship operators successfully identify fuel consumption optimisation opportunities that will reduce operating costs.

Tank switch over: Coriolis meters are multifunctional – as well as measuring mass flow, they are also able to measure density. When considering switching from one fuel type to another during a voyage, continuous monitoring of the density of the fuel currently being consumed is a decisive indicator of when fuel switch over should be made. Density measurement also provides positive feedback when the switch over has been completed.

Accurate density measurement from a Coriolis meter allows fueling decisions to be made that contribute to operating cost savings. It should be noted that the mass flow meter alone will not deliver cost savings. It is the accuracy and reliability of the measurements that allow for instantaneous assessment of the vessels operating cost. According to a very well-known technical director of a Greek shipping company, measures taken from there to reduce cost are key.