From Oil & Gas Expertise to CO₂ Expertise

with the Same Products

Rheonik Coriolis mass flow meters have been established in the global oil and gas industry for decades. This foundation of expertise is key to our competence in Carbon Capture, Utilization and Storage (CCUS). The physical and technical challenges of CO₂ capture, utilization, and storage often resemble those in traditional energy applications – but demand the highest accuracy, process safety, and material integrity. Rheonik has successfully supported a wide range of CCUS projects around the world, delivering tailored measurement solutions for diverse requirements.

Accurate mass flow measurement of CO₂ at each of these stages is essential. Measurement errors can lead to safety risks, process inefficiencies, and compliance issues. Rheonik's Coriolis mass flow meters deliver continuous, precise real-time data – even under extreme conditions such as high pressure, low temperatures, and challenging media. This ensures both economic efficiency and technical integrity of CCUS facilities.

What is CCUS?

CCUS stands for Carbon Capture, Utilization and Storage, a central pillar in global decarbonization strategies. Its objective is to permanently remove CO₂ emissions generated from industrial processes and energy production from the atmospheric cycle. The process consists of three key stages:

- Capture: CO₂ is extracted from flue gases, e.g., during steam methane reforming (SMR) in hydrogen production

- Utilization: CO₂ is used in industrial processes, such as Enhanced Oil Recovery (EOR)

- Storage: CO₂ is permanently stored in geological formations such as depleted reservoirs or salt caverns

Dense Phase, Pipeline, Injection – Measurement Reliability Under Extreme Conditions

In CCUS applications, captured CO₂ is typically transported in its dense phase, under high pressure and low temperature. Measuring the mass flow in this phase is technically challenging, as density, viscosity, and flow behavior differ significantly from conventional fluids. Rheonik systems – especially our high-pressure models – are purpose-built for these demanding conditions.

Typical applications include:

- CO₂ injection into oil and gas reservoirs (EOR)

- Direct injection into geological storage formations

- Monitoring of CO₂ backflow

- Custody transfer and fiscal metering

Enhanced Oil Recovery (EOR) – Using CO₂ as a Strategic Resource

A significant part of CCUS is the use of CO₂ to enhance production in mature oil fields. In Enhanced Oil Recovery (EOR), CO₂ is injected under pressure into the reservoir to reduce oil viscosity and maintain reservoir pressure. This boosts overall recovery and improves the economics of the asset. Precise measurement is critical here as well – especially to control injection volume and rates. Rheonik offers flow systems designed to provide accurate, reliable, and robust measurement under these demanding conditions.

Our Top Products for CCUS Applications

Rheonik Carbon Meter – Engineered for Dense Phase CO₂ and High-Pressure Processes:

RHM 10

Flow Range:

0.25 to 90 kg/min (0.55 to 198 lb/min)

Pressure Rating:

up to 1384 bar (20,073 psi)

Temperature Range:

-196 to 350 °C (-321 to 662 °F)

Process Connections:

1/2" to 1 1/2"

(others on request)

Product Page >

RHM 20

Flow Range:

1 to 480 kg/min (2.2 to 1,058 lb/min)

Pressure Rating:

up to 1137 bar (16,490 psi)

Temperature Range:

-196 to 350 °C (-58 to 662 °F)

Process Connections:

1" to 2 1/2"

(others on request)

RHM 40

Flow Range:

20 to 1,500 kg/min (44 to 3,300 lb/min)

Pressure Rating:

up to 433 bar (6,280 psi)

Temperature Range:

-196 to 350 °C (-321 to 662 °F)

Process Connections:

2" to 3"

(others on request)

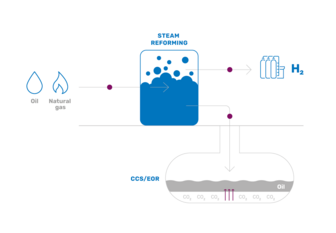

Hydrogen from Fossil Energy via Steam Reforming

One key process where CCUS plays a critical role is Steam Methane Reforming (SMR). In this process, methane (CH₄) – typically from natural gas – is converted with steam at high temperatures inside a reformer. The resulting syngas primarily contains hydrogen (H₂) and carbon dioxide (CO₂). This enables cost-efficient hydrogen production from fossil energy sources but generates significant CO₂ emissions: around 10 tons of CO₂ per ton of hydrogen. In order to classify this hydrogen as "blue hydrogen," the CO₂ must be captured and stored permanently. Rheonik flow meters provide the required precision for accurate measurement of captured CO₂ streams prior to compression and transport.