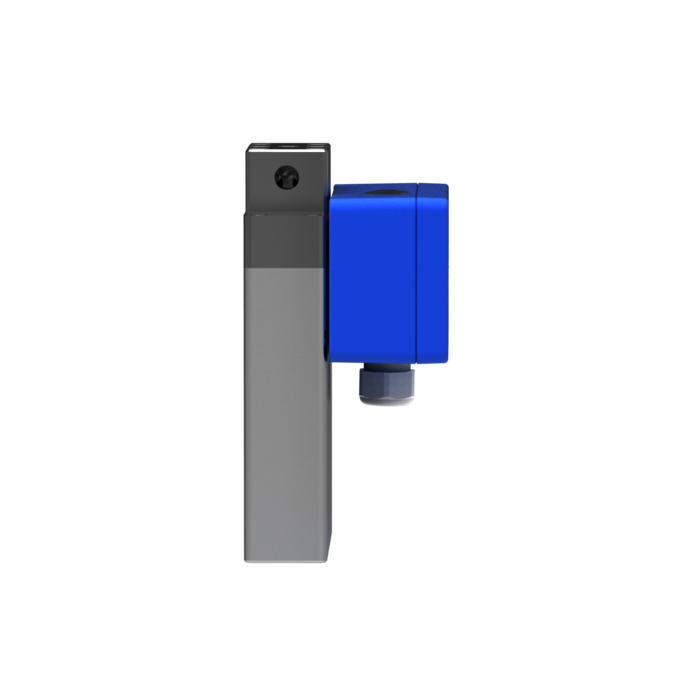

RHM 015

FLOW SENSOR

The RHM 015 Coriolis sensors offers solutions for the lowest flow rates – for flow control, batching and injections up the highest pressures in industry. Small, compact and highest performance.

- Range: 0.002 kg/min up to 1.2 kg/min

- Pressure: up to 1481 bar (21480 psi)

- Temperature: -196°C (-321°F) up to +210°C (410°F)

- Accuracy: 0.1 % of rate

- Materials: SS 316L / SS 316Ti, Alloy C22 – 2.4602, Super Duplex – 1.4410, Sandvik HP160

- Process Connection: ¼" up to 1"

General Specifications

Nominal Flow (Qₙₒₘ)* | 0.6 kg/min (1.32 lb/min) |

Maximum Flow (Qₘₐₓ)* | 1.2 kg/min (2.65 lb/min) |

Typical Minimum Flow (Qₘᵢₙ)* | 0.002 kg/min (0.004 lb/min) |

Serial Tube / Single Path | Flow rates Qₘₐₓ, Qₙₒₘ and Qₘᵢₙ for "serial" sensors will be 50 % of the above listed parallel/dual path version. |

Operating Temperature | Fluid temperature range options cover from -196 °C to +210 °C (-320 °F to +410 °F) |

Ambient Temperature | -50 °C to +80 °C (-60 °F to +180 °F). High temperature version for oven installation up to +210 °C (+410 °F) available |

Pressure Ratings | 1481 bar (21480 psi) – dependent upon material |

Electrical Connection Sensor | M20 x 1.5 standard cable entry for JM, SM terminal box versions Optional entries available : ½" NPT or M25 x 1.5 (only for SM) or ¾" NPT (only for SM) M16 x 1.5 standard cable entry for PM terminal box version Max. cable length to remote RHE transmitter 100 m/330 ft. |

Sensor Enclosure Materials | Stainless steel 304 (standard), SS 316 (optional) Coated aluminum terminal box, SS 316 terminal box (optional) |

Enclosure Type | Protection class IP 66, NEMA 4 (standard), IP 66/67, NEMA 4X (optional) |

Wetted Materials | Flow tubes SS 316 L, SuperDuplex, Sandvik HP160® or Alloy C22 Manifolds SS 316 L, seals FKM, FFKM, FVMQ, EPDM Standard flanges SS 316 Ti, other connections SS 316 L Additional/customer specific materials available upon request |

Process Connections | Nearly any – the Rheonik AnyPipeFit Commitment. Consult factory for types/sizes not listed in this data sheet on the Mechanical Construction pages |

Pressure Rating Compliance | PED 2014/68/EU Article 4, Section 3 (SEP) |

Certifications and Approvals | ATEX / IECEx Approvals Zone 0, 1, 2 (see datasheet) North American Approvals Cl. I, Div. 1, 2, Gr. A, B, C, D, Zone 0, 1, 2 (see datasheet) American Bureau of Shipping (ABS) |

Testing and Inspection | All sensors are hydro tested, calibrated and supplied with a traceable calibration certificate. Customized calibration and testing services are available |

Project Documentation and QA, Services | Rheonik offers a full set of services for large and complex engineering projects.

|

Options | Customization services for machine integration. Consult factory |

* At Qₙₒₘ pressure drop across a parallel tube sensor will be approximately 2 bar (29 psi) for H₂0. Sensors can be operated at higher flow rates up to Qₘₐₓ but pressure drop will be higher. Typical Minimum Flow Qₘᵢₙ is the recommended lowest flow rate for an accurate measurement. Sensors will measure flow rates lower than Qₘᵢₙ but uncertainty will increase beyond 1 % of rate.

The flow rate specifications above relate to standard pressure, parallel tube, manifold sensor versions. Models with higher pressure ratings have increased wall thickness and will have higher pressure drops.